8 September 2016

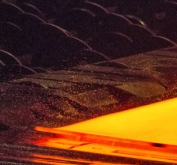

Ilyich Iron and Steel Works of Mariupol (MMKI) of Metinvest Group has launched the first phase of Hot Strip Mill (HSM) 1700 modernization. The large-scale upgrade of rolling equipment for HSM 1700 will include installation of modern coiling equipment able to handle coils up to 27 t. Major overhaul of Reheat Furnace No.1 will be part of the second phase. Total project investments for the coming year will amount to c. UAH 120 million.

Ilyich Iron and Steel Works of Mariupol (MMKI) of Metinvest Group has launched the first phase of Hot Strip Mill (HSM) 1700 modernization. The large-scale upgrade of rolling equipment for HSM 1700 will include installation of modern coiling equipment able to handle coils up to 27 t. Major overhaul of Reheat Furnace No.1 will be part of the second phase. Total project investments for the coming year will amount to c. UAH 120 million.

Wide-strip mill 1700 of MMKI can produce steel sheets in coils weighing up to 17 t. However, the maximum coil weight is a limitation to existing strip coiling equipment (up to 9.5 t). This does not allow to meet the customers’ need for heavier and better quality coils.

High-performance equipment for coiling hot-rolled strip will help increase the productivity of HSM 1700 and increase the weight of the rolls in the first stage to 17 tons. On September 08, MMKI signed a contract with Novokramatorsk Heavy Machine Building Plant (NKMZ), one of the largest heavy equipment manufacturer in Ukraine and in the world. The coiling equipment to be manufactured by NKMZ will be equipped with high-precision sensors and will be fully automated.

NKMZ will develop basic and detail engineering, manufacture and supply the equipment. The design documentation for installation works will be developed by Metinvest Engineering. The project assumes manufacture and installation of hot-rolled steel coiling machine for UAH 80 million. The production of the first heavy coil is scheduled in the late 2017.

New equipment will improve the quality of coiling, and reduce the risk of product damaging at transportation. The upgrade of HSM 1700 will help reduce the cost of hot- and cold-rolled coils. The coil weight will be increased to 27 t in the future.

MMKI General Director Yuriy Zinchenko:

- We launched an ambitious program to modernize our steelmaking operations. Basic oxygen furnace No.2 is under major overhaul at the moment. We signed a contract with our Austrian partners for the construction of a new continuous casting machine to implement best available techniques with respect to efficiency, safety and environment. Steel quality and cost advantages that will be made tangible due to modernization will need to be further utilized in rolling operations. The goal is to increase our sales of premium class high value-added products.

As a reminder, MMKI signed a contract on September 05, 2016 with Primetals Technologies Austria GmbH, a worldwide leading manufacturer of equipment for ferrous and non-ferrous metallurgy, for the construction of a two-strand continuous casting machine (CCM). Total project investments are over $150 million. The new CCM will produce 2.5 million tons of premium slabs for re-rolling on HSM 1700.